Permanent Suspension Magnets are suspended over belt conveyors or over roller conveyors prior to metal detector to trap all free large ferrous / iron particles that may damage the in process machinery & its parts.

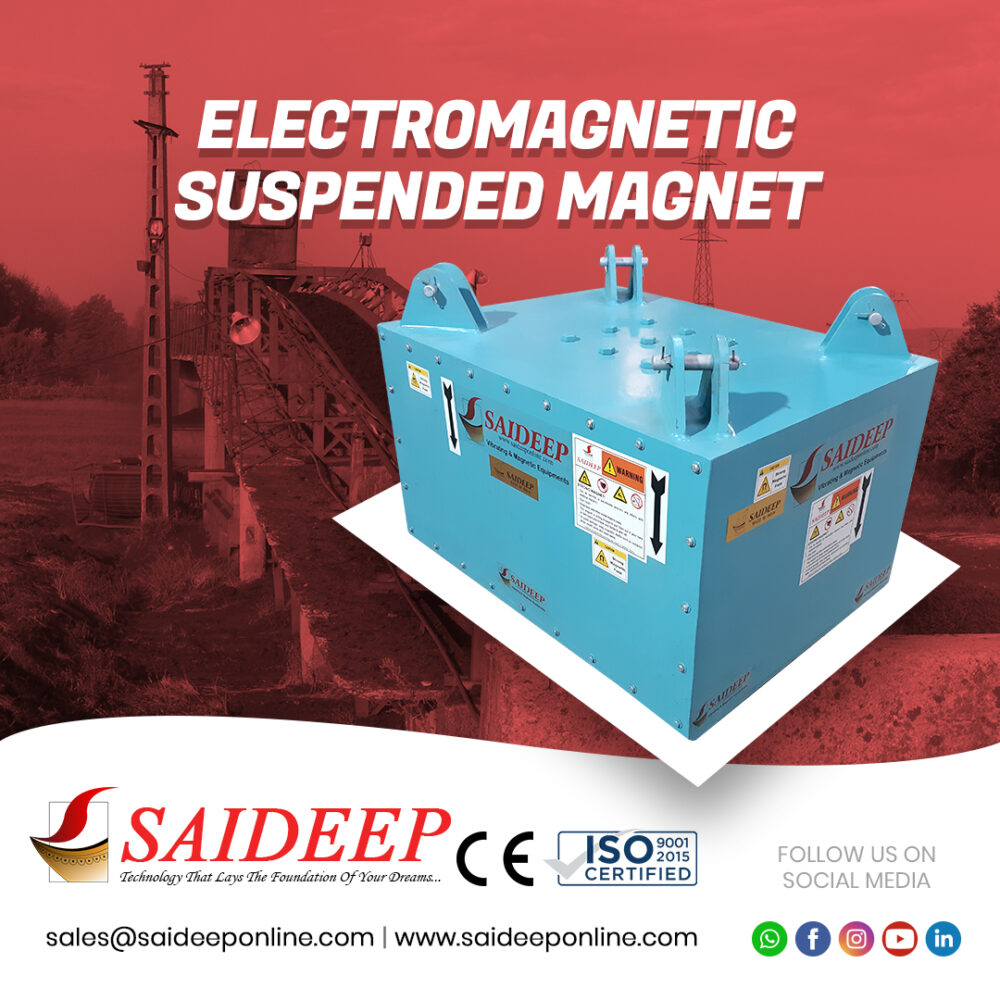

Suspension Magnet

Suspension Magnets are back bone of continuous process industry.

The permanent magnetic suspension magnets are suspended over conveyor line and are used to remove iron impurities mixed with product moving on conveyor belt. It can also be used for any other material feeding system to avoid damage to the crushers, grinders and other material handling equipment. These magnets can be made in self-cleaning design if required (Over band Magnetic Separator).

Features

The magnetism in a permanent suspension magnet is produced by internal assembly of magnets enclosed in a non-magnetic stainless steel housing. The magnet is suspended by turnbuckle, dee shackles, wire ropes and suspended hooks.

The magnetic power in suspension magnet is designed according to material depth/belt speed of the conveyor. Operating heights up to 400 mm, are possible. The suspension magnet can also be used in conjunction with magnetic pulley to achieve 100% results.

Specifications

- Belt Width Range: 400 mm to 1500 mm

- Operating Height Range: 100 mm to 400 mm (Minimum Gauss Value at Operating Height must be over 400 Gauss)

- Magnet Type: Strontium Ferrite Magnets

- Gauss Power: 2500 Gauss (+/- 10%)

- Recommended Magnet Lengths in correlation to Operating height

- Operating Height 100 mm: Magnet Length 500 mm

- Operating Height 150 mm: Magnet Length 550 mm

- Operating Height 200 mm: Magnet Length 800 mm

- Operating Height 250 mm: Magnet Length 1050 mm

- Operating Height 300 mm: Magnet Length 1300 mm

- Operating Height 350-400 mm: Magnet Length 1500 mm

- All Suspended Magnets are equipped with two Adjustable & two Fixed Turn Buckles with a Bull Ring.

- Optional Upgrade: Manual Slide Sheet

Applicable Areas/Domains

- Aggregate | Quarry or Coal Crushing & Screening Lines

- Bagasse Processing Lines

- Sugar Processing Industry

- Sand Washing Lines

- Cement Industry

- Plastic Recycling Lines

- Rubber Reclaim Units

- Mining Industries

- Food & Agro Processing