Bin Activator

Some materials when stored within Hoppers, Silos or Bins do not flow out easily due to the peculiar design of the storage vessel or due to the inherent non-flowing properties of the material. When stored for prolonged durations some materials also tend to compact or react with the storage vessels. In such situations it is recommended to use Bin Activators that help ease the flow of materials which may have been clogged due to Bridging, Rat Holing or Compaction.

Bin Aerators

Saideep’s Unique umbrella shape Bin Aerator provides dual advantage of cleaning side walls of silo and fluidizes the material simultaneously, guaranteeing uniterrupted flow of material through silo cone.

Circular Vibro Screen

Vibro Screen is also known as Gyratory Screen, Vibro Sifter, Circular Screen Separator etc.

SAIDEEP Screen Separator is a unique particle size gradable separator designed for greater capacity per meter square of screening area & over size material discharge with relatively much less percentage fines than other screening machines.

Our company has ACED in manufacturing and supplying a vast variety of screen separator to various industries across the country. We offer horizontal screen separator and circular screen separator which come with many special features. Our screen separator is known for their high performance, innovative designs, and affordable prices making them extremely popular among customers.

Tumbler Screen

The Tumbler Screening Machine is a unique sieving equipment that is capable of screening High & Low Bulk Density powders with extreme high efficiency. It helps grade or separate materials in multiple fractions as desired or as based on the application.

The powders or granules are continuously fed into the centre of the screen & the tri-planer elliptical movement of the screen helps spread out the material uniformly. Due to the said motion created all fines pass through the sieve & the coarser moves towards the circumference of the decks.

The 3D weight-adjustment system allows the users to set the sieve movement intensity & the entire system is driven with the help of an Electric Motor & V-belts linked to the shaft. The Tumbler Screens are available in 36 inch & 48 inch diameters with optional MOC in Mild Steel (MS) OR Stainless Steel (SS 304 / SS316L).

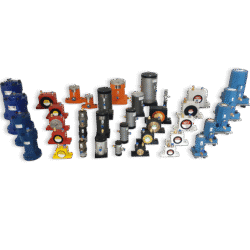

High Frequency Vibrators

External High Frequency Pneumatic & Electric Shutter Vibrators are used for construction of concrete segments for tunnels, viaducts and bridges.

Vibrator Motor

Saideep Vibrators Pvt Ltd presents premium Unbalanced Vibrator Motors ranging from 0.04 kw to 10 kw with a Centrifugal Force up to 1,30,000 N. These robust Industrial Electric Vibrators are manufactured in 2 Pole, 4 Pole, 6 Pole, and 8 Pole designs. Confirming to International Standards, our Vibro Motors (Standard & Milling Series) are CE Certified, ATEX Approved and exported all over the globe.

Inline Vibro Screen

A Low Profile Separator offers high capacities of wet or dry scalping in a low headroom design. The low profile separator has a single vertically mounted motor to generate a sifting motion across the screen plane.

These Inline Vibrating Screens fit neatly into production lines, providing considerable screening capacity without requiring excessive headroom. Operating and cleaning is quick and easy, making this range of separators perfect for all processing industries and application like pre-packing screening, bulk bag unloading and screening of raw ingredients.

Pneumatic Vibrators

SAIDEEP VIBRATORS PRIVATE LIMITED manufacturers Pneumatic Vibrators of various types & models such as:

- Ball Type Pneumatic Vibrator

- Turbine Type Pneumatic Vibrator

- Piston Type Pneumatic Vibrator

- Impact Type Pneumatic Vibrator

- Cushioned Pneumatic Vibrators

- Hammer Type Pneumatic Vibrator

- Roller Type Pneumatic Vibrator

- Pneumatic Air Knocker

- Pneumatic Linear Vibrator (with Adjustable Mass)

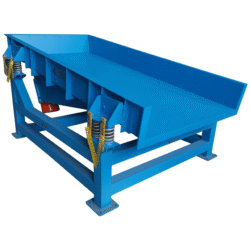

Rectangular Vibro Screen

‘SAIDEEP’ Rectangular vibrating screens offer a highly efficient approach to screening. This single development has resulted in tremendous advantages as far as reduced maintenance, compactness and simplicity are concerned. Besides the simplicity of the drive, many other features have been incorporated to provide a machine which is specifically designed for heavy duty applications, long life, and low operating and maintenance costs, at a competitive price. The standard range of screens is presented later in the brochure, and these are normally available on short delivery.

Vibrating Feeder | Conveyor

The Motorized Vibratory Conveyor consists of a horizontal tray made of mild steel or stainless steel. The horizontal tray is fixed to the frame, The vibrations are provided by two special unbalance motors fixed on either sides of the tray. The complete assembly of tray with motors rest on a set of coil springs so that, no vibrations are transmitted to the stand and ground. As the Motor starts, the vibration sets in motion. Controlling of vibrations gives the controlled flow of the material. The housing of the motor is in totally enclosed design.

Useful to any continuous process industry where bulk conveying of material or powder is required.

Vibratory Spiral Elevator

The Motorized Vertical Spiral Conveyor consists of a number of spiral trays which is made of mild steel and a main body attached with vibrating motor which is connected to the the upper spiral tray body, As the Motor starts, the vibration sets the material in spiral upward motion. The body housing of the motor is totally enclosed design to prevent dusting. The motorized spiral conveyor screen works on standard frequency of 3000 vibration per minute with max. amplitude of 1.5 mm. to 2 mm. depending on the size of the screen.

Useful to any continuous process industry where vertical elevating of material is required.

Diamond Shape Sorting Machine

We have pleasure to introduce ourselves as manufacturer of Diamond shape sorting machine, which is used for sorting diamonds according to their shape. The machine is very useful for our clients who deals in bulk quantity of diamonds as the tedious and time consuming manual work of shape sorting can now be done with the help of this machine

This Machine is being used by several reputed diamond traders.

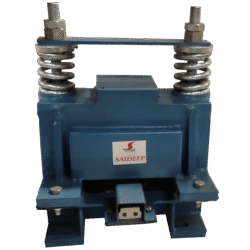

Vibrating Table

Electromagnetic vibrating table consist of solid base plate and a vibrating top. The top platform vibrates at 3000 vibrations per minute through an electromagnet housed inside. Each table is supplied with a control panel, which supplies pulsating current to electromagnet and also controls the amplitude of vibration. Control panel operates on 230 V.A.C. single phase.

Used for packing of products. Testing of welding joints. Eliminating vords in moulded parts. Achieving uniformity in ceramic moulded parts.

Vibrating Feeder

The Electromagnetic Vibratory Feeder consists of a specially designed robust electromagnetic coil & custom crafted tray made of mild steel or stainless steel. The tray which is connected to the armature of the drive vibrates as the magnetic coil gets energized. The vibration sets the material in motion. Vibrations can be controlled through variable voltage controller for vibrating feeders. The casting housing the electromagnet is made in totally enclosed design to prevent dusting.

Useful to any continuous process industry where automatic controlled flow of material is required.

Impact Type Vibrator

The Electromagnetic impact type vibrator consists of main body which houses the coil. The coil is fed with pulsating current that sets in the vibration. The amplitude of vibration can be controlled by controlling the input voltage. The vibrators are easy to install and use and need no maintenance. The intensity of vibration can be varied if needed by providing regulator in the control panel.

Most ideal for declogging of hoppers and chutes Used for conveying products which will not normally move on slope.

Drawer Magnetic Grill

Drawer-in-housings are used primarily in vertical chutes for removal of free flowing bulk materials. The drawer in housing designs are offered in simple, inexpensive manually cleaning designs, easy clean, or air or electrically actuated automatically cleaning designs. Food grade finish is available as is any number of tube configurations to optimize the design for your product. The standard tube configuration is staggered so the material must flow around the tubes and tramp metal removal is maximized.

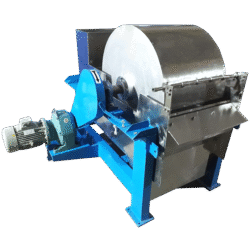

Drum Type Magnetic Separator

Saideep Magnetic Drum Separators are used for automatic separation of Iron Particles from products & materials that have a high percentage of ferrous contamination present within. Generally Magnetic Drums are used for continuous process lines to remove iron from heavy material flows. These magnetic drums can be provided to customers in various design and sizes to best suit their product demands & functional requirements.

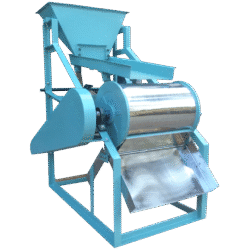

Magna Roll | Magnetic Destoner

Saideep Magna Roll Separators aka Magnetic Destoners are roll type magnetic separators with fixed magnet having high field intensity and gradient. The magnets used in the Roller Magnetic Separators and made of High Grade Rare Earth Magnets. They generate high attraction forces on the magnetic roller due to their properties and special magnetic series. The obtained high magnetic attraction forces have low magnetic sensitivity and therefore they make it possible to separate very fine low magnetic minerals with a high recovery.

Magnetic Chute & Plate

Saideep Super Power Rare Earth Magnetic Plates are used in process lines to trap iron contamination from chutes, spouts, ducts, pipe lines, or can be closely suspended over belt conveyors. These magnetic plates help safe guard the process machinery or the downstream equipment for iron parts that can damage parts of running machines such as blades / shredders / pulverizers / grinding equipment.

Magnetic Plates are manufactured in different gauss powers & are selected based on the type of ferrous contamination that needs to be eliminated. The iron contamination may be in form of small particles such as mudballs or pins or grinds, they can be in the form a medium sized particles such as screws, washers, broken chipped machine parts or can be found in large segments. Ideally the plate magnets are designed for the material to flow in contact with the surface plate of the magnet, however it can also be used by suspending it over the material in close proximity.

Magnetic Grills

Our Super Power Rare Earth Magnetic Grids are useful for removing very fine weakly magnetic impurities from free flowing powder and granular material. Magnetic Grids are assembled from 1” Dia Rods in SS – 304 o SS – 316 Material having super power Magnetic force on the surface. These grids can be made rectangular, Round and Draw out type grids for easy cleaning to suit customer’s application and are available in single or multiple rows, fitted in housing as shown. Rare Earth magnetic grids are used to purify products such as Food, Chemicals and Minerals. These grids are also used in other Industries such as Foundries, Glass, and Plastic etc.

The rods could be given in assembled form Rectangular or Round shape to form grid to suit hopper design. The grid has rare earth magnet rods so designed to arrest even the finest particle going with the product.

Magnetic Hump

Magnetic Hump is used for removing tramp Iron mixed with powder flowing down the vertical pipe. Magnet consists of two Super Power Rare Earth Magnetic Plates hinged on the zigzag path. The hinged magnetic plate can be opened and cleaned easily.

When the material falls it strikes directly on the first magnet plate. Major Iron contamination gets deposited here. The material then flows to the second magnet where escaped Iron particles are removed. This insures a clean Iron free material.

Magnetic Pulley

Saideep manufacture a wide range of Rare Earth and Ferrite Magnetic Pulleys. These Pulleys are widely used to remove tramp iron mixed with the material moving on a conveyor belt.

The Magnet pulleys are always installed at the discharge point of the conveyor to separate tramp iron from the product moving on the conveyor belt.

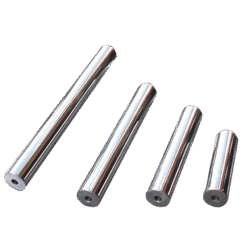

Rare Earth Magnetic Rod

Saideep has come out with the most powerful range of Magnetic Separators using Rare Earth Magnets. Magnetic Rods have Rare Earth magnets inside with magnetic power up to 12000 Gauss. The rods can be manufactured in any length.

Suspension Magnet

Suspension Magnets are back bone of continuous process industry.

The permanent magnetic suspension magnets are suspended over conveyor line and are used to remove iron impurities mixed with product moving on conveyor belt. It can also be used for any other material feeding system to avoid damage to the crushers, grinders and other material handling equipment. These magnets can be made in self-cleaning design if required (Over band Magnetic Separator).

Wet Drum Magnetic Separators

The wet drum magnetic separator is ideally used to separate ferrous particles from non ferrous particles. They are so made by us to provide ultimate protection to crushers, Grinders, Pulverizers and allied equipment and is useful for mining and ore dressing industry. It is so made that one side is magnetized and the other side is not.

Over Band Magnetic Separator

Suspended Over Band Magnetic Separators are designed for applications where ferrous contaminants are to be removed from bulk products – either on a moving conveyor belt or chute.

They utilize a permanent magnet circuit to provide a continuous and uniform magnetic field across the feed belt to optimize separation efficiency of damaging tramp iron.

The self-cleaning feature supplied with the unit provides for automatic removal of accumulated tramp metal.