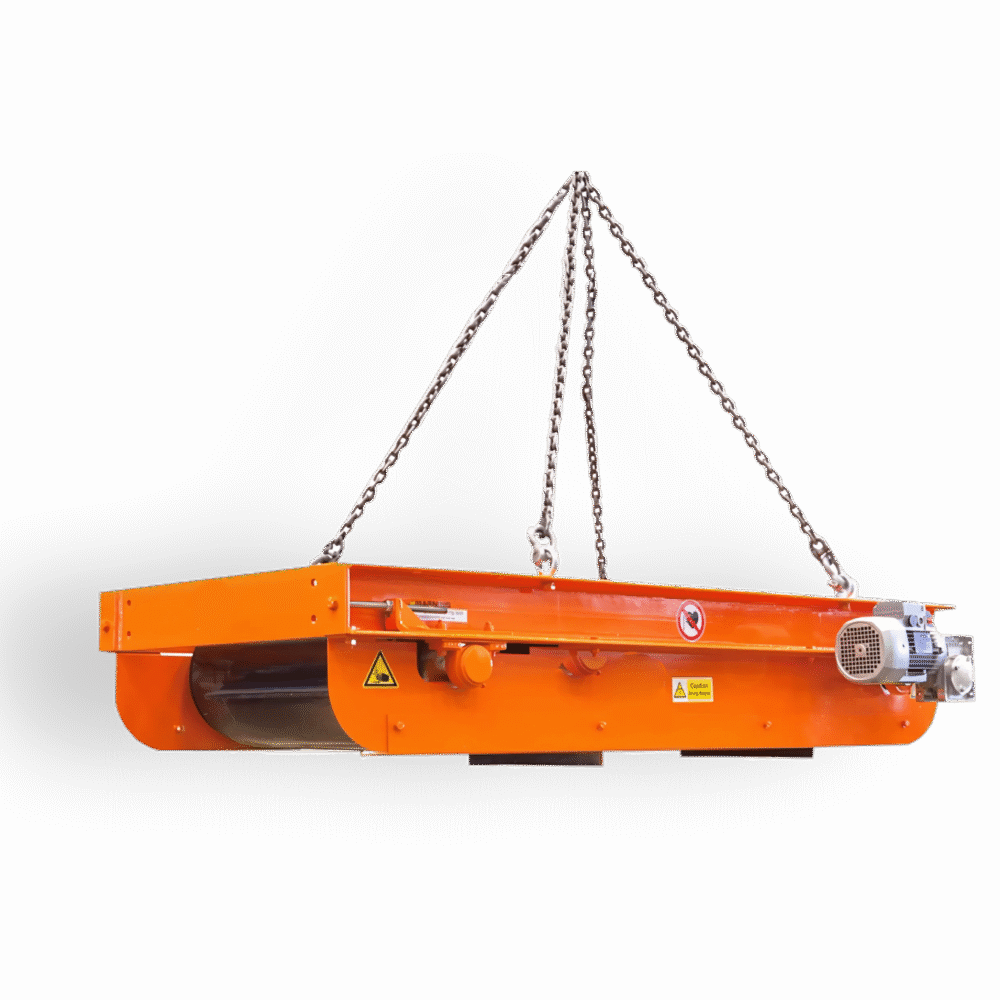

Overband Magnetic Separators are used in sectors wherein a large volume of Iron Contamination needs to be removed from material flowing over a conveyor flat or angular belt. The OBMS is recommended in applications where the size of the ferrous material is large.

The Overband Magnetic Separators are compact & well housed magnetic separators that allow self clearing of ferrous materials rather than being removed manually from the magnets surface. The OBMS can be placed perpendicular or inline with the conveyor below flow. The iron particles are attracted to the OBMS when they are under the Magnetic Zone & then driven away by the rotating belt of the OBMS into the Non Magnetic Area automatically.