Electromechanical Vibrating Feeders are robust, maintenance free & highly durable. These feeders are capable to provide high throughput material feed with higher amplitudes. Their flexible & custom designs help achieve & cater product specific demands.

Vibrating Feeder | Conveyor

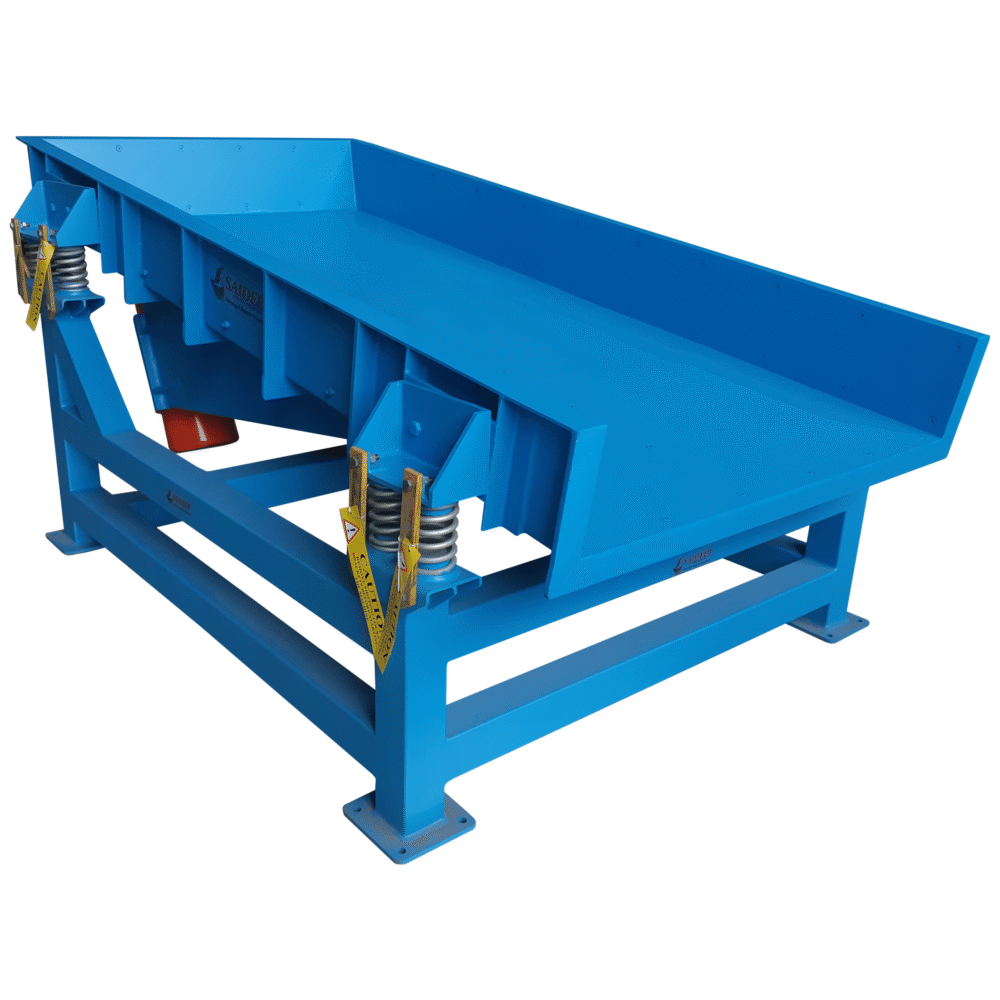

The Motorized Vibratory Conveyor consists of a horizontal tray made of mild steel or stainless steel. The horizontal tray is fixed to the frame, The vibrations are provided by two special unbalance motors fixed on either sides of the tray. The complete assembly of tray with motors rest on a set of coil springs so that, no vibrations are transmitted to the stand and ground. As the Motor starts, the vibration sets in motion. Controlling of vibrations gives the controlled flow of the material. The housing of the motor is in totally enclosed design.

Useful to any continuous process industry where bulk conveying of material or powder is required.

Features

- Max Design Capacity: Up to 600 Tons/Hour

- High Conveying Speeds: Up to 30 Meters / Minute

- Max Conveying Length: Up to 12 Meters

- Custom Trough Designs: Pan Tray, ‘V’ Tray, Scarf Tray, Tubular Trough

- Liner Options: C45, Sail Hard, Hardox, Polymer etc

- Drive Type: Vibrator Motors CE & ATEX Certified

- Various Isolation Types: Coiled Springs, Oscillation Mounts & Rubber Marshmallows

- Mounting Type: Base Mounted or Suspension Mounted

- Optional Upgrades: Hygienic Sanitary GMP Designs, Clean In Place Accessories, Special Design for Hazardous Environments, Quick Release Dust Covers.

Applicable Areas/Domains

Motorized Vibratory Conveyors are very useful in industries & areas such as:

- Snack Foods, Nuts & Food Industry

- Grain & Rice Milling Industry

- Rubber Reclaim

- Glass Industry

- Crushing, Screening & Mining Industry

- Sugar Industry

& many more