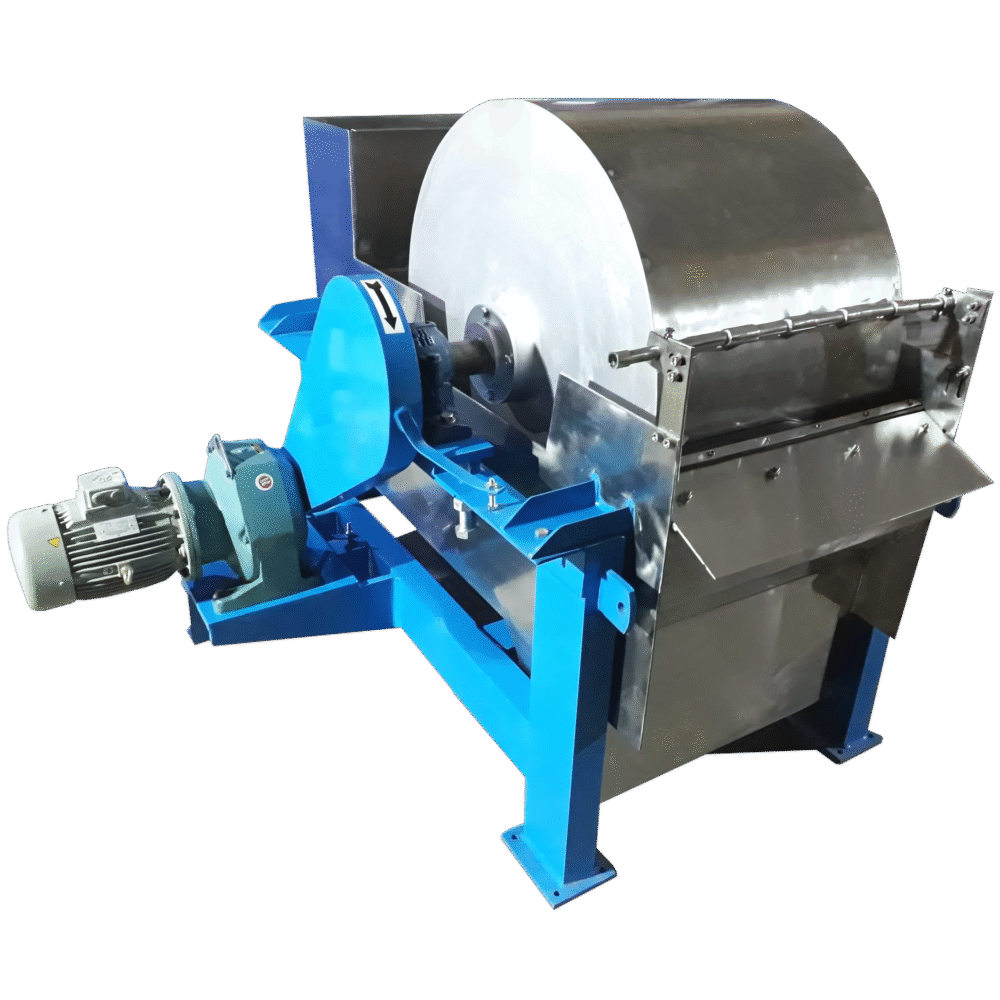

Only one side of the magnetic drum is magnetized and the other side is not magnetized. The stainless steel 304 shell which surrounds the magnet rotates freely and the magnet is stagnant. The ferrous particles that get attracted to the magnet are collected separately.

Wet Drum Magnetic Separators

The wet drum magnetic separator is ideally used to separate ferrous particles from non ferrous particles. They are so made by us to provide ultimate protection to crushers, Grinders, Pulverizers and allied equipment and is useful for mining and ore dressing industry. It is so made that one side is magnetized and the other side is not.

Features

It conveniently removes the ferrous particles from the non ferrous powder and crystals and is ideal for Food, Fertilizer, Plastic, Pharmaceutical, Chemical and continuous process plants. It gives maximum protection to crushers, Grinders, Pulverizers, and allied equipment. It also proves to be helpful in mining and ore dressing industry and eliminates fire hazards and explosions in such plants where explosive materials are dealt. It saves time, labor, money since it reduces the chances of breakdown and has improves quality. These machines have a capacity to pay back in very short span of time.

The magnetic drum separator consists of a number of oriented, isotopic permanent magnets that are assembled to give alternate polarity across the circumference dependent on the application. The magnetic intensity of the electro magnets is not all that more than permanent magnets. As rectifier and electricity is not used to operate this machinery hence they operate at low costs and also during power failures.

Specifications

The size and capacity of a magnetic drum is decided depending on the following parameters-

- Size

- Type

- Quality of the material to be handled

- Type of separation

- Purification

- Concentration

- Type, size and quality of ferrous combination

- Tramp iron removal

Applicable Areas/Domains

It is ideally used in Ceramic, Chemical, Glass, Fertilizer and food industry separates iron particles from granules and powder. The magnetic drums are suitable for capacities up to 2tons per hour can be given on short deliveries. They have a varying dimension of 300mm. To 600mm. The diameter and length varies up to 1500mm and has a capacity to handle 10 tonnes.