Benefits

The following are the benefits of Vibratory Screen Separator are:

- Low power consumption.

- Varied range of applications.

- High processing rate per unit area of screen.

- Accurate separation.

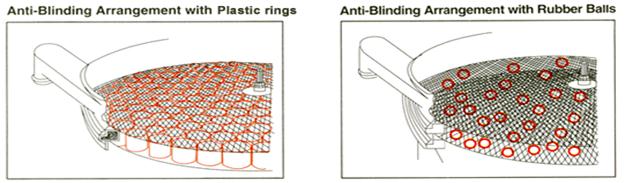

- Minimum screen building.

- Ball/PVC Pipe tray for anti blinding.

- Modular design to yield to multiple predetermined fractions.

- Dust-free and noiseless processing within closed circuit can be achieved.

Working Principle

The motivation is through a unbalanced motor with a double extended shaft, fitted at both ends with eccentric weights .The top weight on the motor shaft rotates in a plane close to the centre of the mass of assembly. Rotation of the top eccentric weights creates vibration in the horizontal plane, which causes material to move across the screen cloth to periphery increasing the horizontal throw, causing oversized material to discharge at a faster rate.

The bottom eccentric weight rotates below the centre of mass creating tilt on the screen giving vibration in vertical and tangential plane. Increasing the vertical component of motion, this promotes turnover of material on the screen surface helping maximum quantity of under size material to pass through the screen. Rugged Springs placed over the circular motor base amplifies the vibration.