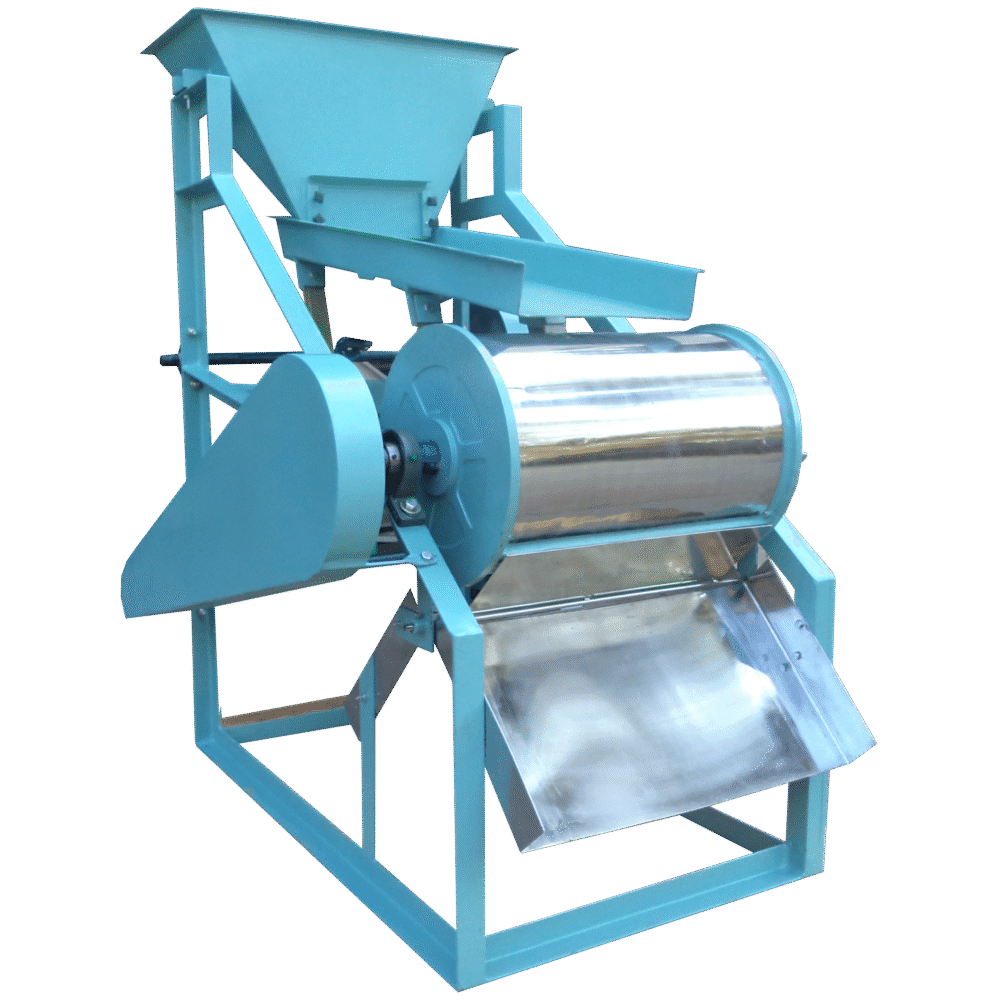

Magnetic drum separators provide an efficient means for extracting ferrous material from dry, bulk products in free-flowing processing systems. They are comprised of a stationary permanent magnet, either standard Ferrite Magnets or High Power Rare Earth Magnets enclosed in a non-magnetic stainless-steel drum. Product flow is diverted so that it falls onto the top and flows across the surface of the drum. Ferrous matter contained in the product flow is drawn to the drum’s surface (and held against it) by the powerful magnet housed inside.

While non-ferrous products falls from the side of the drum in a normal manner, ferrous metal clings to its surface. As the portion of the drum with the ferrous material rotates to the side opposite the product flow, the magnetic field is reduced so that the ferrous matter falls from the drum into a collection container. The end result is purified product ready for processing without the worry of costly damage caused by tramp metal.