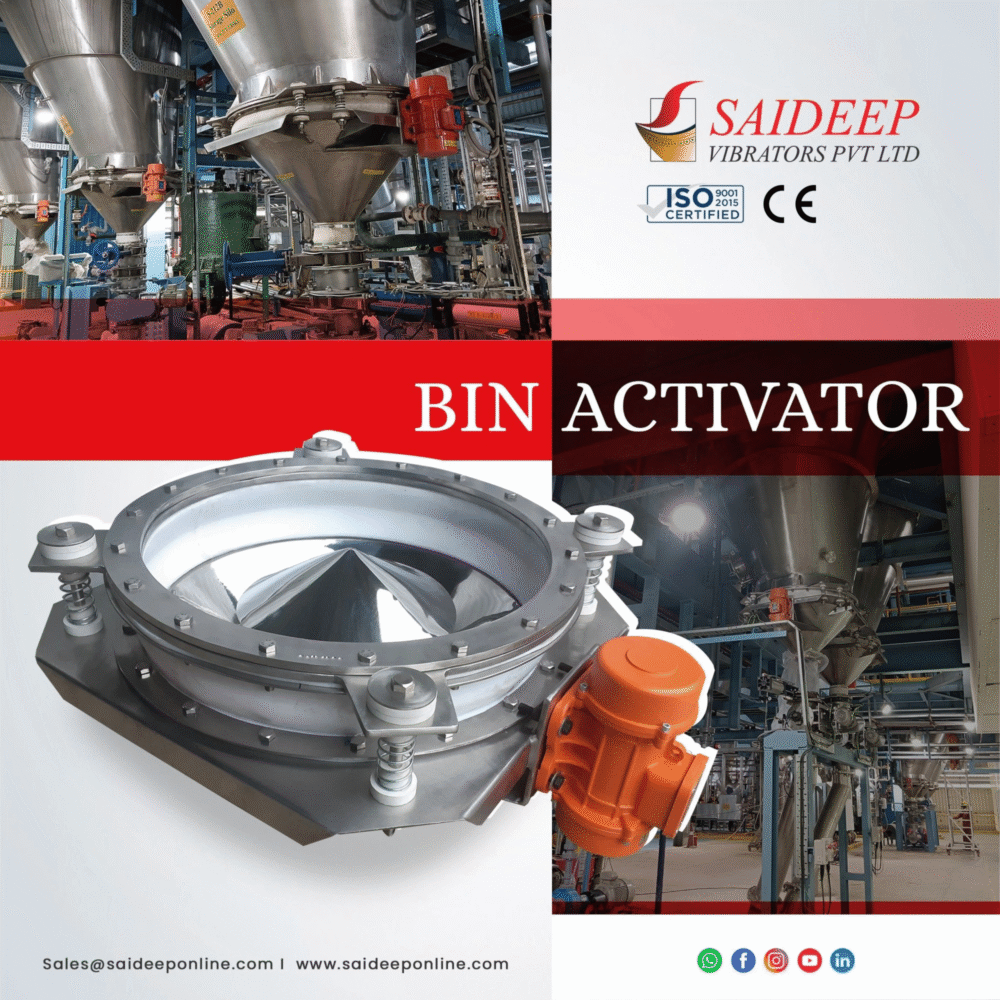

Product Overview

Bin Activators consist of conical shape discharge zone which is connected to the Silo / Hopper via a set of suspension hanger. The gap between the Silo / Hopper and the discharge cone is sealed with the help of Rubber Gaskets (Bellows). The inverted adjustable baffle cone vibrates through the stored materials allowing the jammed products to flow out of the Bin Activator.